Baume & Mercier Watches at Gerald Peters

July 3rd, 2015

Introducing Baume & Mercier

Baume & Mercier logo. (PRNewsFoto/Baume & Mercier)

Gerald Peters is proud to now offer Baume & Mercier, the internationally recognized and esteemed and seventh oldest Swiss watchmaking brand in the world.

WATCHMAKING HERITAGE AND KNOW-HOW SINCE 1830

Baume & Mercier enjoys international recognition and is the seventh oldest Swiss watchmaking brand. Baume & Mercier, a family saga, has been making its mark on watchmaking history since its inception. We are committed to perpetuating this heritage and continuing to pass down this know-how to future generations.

"Accept only perfection, only manufacture watches of the highest quality"

ORIGINS 1830

Baume & Mercier's story begins in 1830 with the founding of a family business. Brothers Louis-Victor and C?lestin Baume opened a comptoir horloger (watch dealership) in Les Bois, a village in the Swiss Jura. Their company developed rapidly and earned an excellent reputation by creating exceptional models incorporating cutting-edge innovations. Loyal to their motto "Accept only perfection, only manufacture watches of the highest quality", the Fr?res Baume company enjoyed rapid growth. Louis-Victor was a true visionary who already intuitively sensed women's interest in watchmaking and gifted his daughter M?lina a gold pocket-watch in 1869.

INTERNATIONAL EXPANSION

Keenly aware of the potential represented by new territories, the company set up a branch in London under the name "Baume Brothers". It soon expanded throughout the British Empire, spanning India, Africa, Australia, New Zealand, Singapore and Burma. By the late 19th century, the company had already acquired a solid international reputation and was becoming a noted watchmaking player abroad. At the time, the brand was best known for its chronographs and its grand complication models, including minute repeaters, calendars and tourbillons. Thanks to its time measuring instruments, the company won ten Grand Prix awards and seven gold medals at international exhibitions and shows in Paris, Melbourne, Zurich, London, Amsterdam and Chicago.

As well as being beautiful and highly complex, Baume watches also demonstrated a rare degree of precision. They set accuracy records and won various timekeeping competitions, particularly the precision timing trials held by the Kew Observatory near London. In 1892, Baume won the latter competition with a chronometer pocket-watch equipped with a tourbillon movement of which the precision was to remain unmatched for over ten years.

NEW ENCOUNTER, NEW DISTINCTION

At the beginning of the 1920s, the company director William Baume joined forces with Paul Mercier. Together, they founded Baume & Mercier, Gen?ve in 1918. The firm soon became one of the most active in the field of wristwatches by offering remarkably balanced special-shaped models. In 1919, it was awarded the highest international distinction of the time in the shape of the "Poin?on de Gen?ve" quality hallmark - a token of exceptional craftsmanship and quality.

CREATIVITY AND FEMININITY

Paul Mercier knew that it was essential for the brand to live in step with the times and to embrace change. During the "Roaring Twenties", the brand grasped the importance of women's emancipation and came to regard their desires as an unquenchable source of inspiration. In the 1940s, building on this profound understanding of femininity, Baume & Mercier launched one of its most successful models: the Marquise. This jewelry-watch nestling inside a bangle-style bracelet was both attractive and practical

Impelled by this creative momentum, the brand launched a number of exquisitely creative and amazingly modern ladies' watches. It thereby proved that timepieces for women are not merely miniaturized and simplistic interpretations of masculine models. Femininity was already an integral part of the Baume & Mercier values - revealing a resolutely modern attitude.

ORIGINALITY AND AVANT-GARDE

Energized by the arrival of Paul Mercier, the company laid the foundation of a corporate philosophy that is still as timely as ever. From this point onwards, horological mastery was embodied through timeless elegance. A true trailblazer in this market segment, Baume & Mercier made a name for itself among a public eager for new products by launching the first "shaped" (meaning other than round) wristwatches.

During the entire Art Deco period, the brand asserted its style and left an enduring imprint on the field of watch design. Witness the Hampton collection, inspired by a rectangular watch launched in the 1940s. This chic, urban watch with its timeless design keeps step with the life's many special moments by embodying an art of living instilled with inimitable elegance.

CLASSICISM AND MODERNITY

During the 1950s and 60s, the company was constantly in pursuit of the equilibrium symbolized by the Greek letter (Phi) - the current Baume & Mercier logo - laid the groundwork of what is now considered the archetypal traditional round watch. It thus launched various chronographs equipped with functions such as moon phases or triple date displays, as well as collection of round watches with a simple design and pared-down dials. These emblematic Golden Fifties watches now enable the brand to return to its roots and gain inspiration from the past in creating collections such as Capeland and Classima, as well as the new Clifton line.

ELEGANCE AND TIMELESSNESS

During the 1970s, Baume & Mercier offered innovatively shaped timepieces such as the Galaxie and Stardust models. Perfectly mirroring the brand's inherent creativity, these models won prestigious international distinctions such as the Golden Rose of Baden-Baden. In 1973, Baume & Mercier anticipated societal changes by presenting the Riviera, one of the world's first steel sports watches. In 1988, the firm joined the Richemont group and enriched its collection with a number of successful models which immediately established themselves as the brand's flagship lines.

Baume & Mercier currently offers five collections designed to offer the best possible representation of quality watchmaking: Hampton, for shaped watches intended for both men and women; Capeland, for chronographs and Worldtimer watches; Classima for those with a penchant for minimalist design; Linea for elegant and dynamic women; and finally, the new Clifton collection matching the expectations of urbanites looking for a classic yet contemporary timepiece.

THE SWISS-MADE EXCELLENCE

Baume & Mercier always strives to make an imprint on its times. The founders, brothers Louis-Victor and C?lestin Baume, loyal to their motto "Accept only perfection; only manufacture watches of the highest quality," set out a very precise definition of the watches to be produced by this firm, established in 1830 and now one of the oldest in Switzerland.

A visionary, Louis-Victor was the first to use the L?pine caliber in the Jura. He already intuitively sensed the potential of women's interest in watchmaking by gifting his daughter M?lina a gold pocket-watch in 1869. This decisive choice, particularly reinforced by innovative designs during the period 1920-1940, undoubtedly gives particular strength to the ladies'watchmaking collections today.

Also known for its complication watches, Baume & Mercier has excelled in the art of watchmaking with its chronographs, minute repetitions and chronometers. Baume & Mercier also filed a large number of patents that have since fallen into the public domain for inventions such as the one named "Planetary Rotor" in 1965, designed to fit extra-flat automatic timepieces.

Made in Switzerland since their foundation, Baume & Mercier watches have constantly won awards at the various international Exhibitions or competitions launched by chronometric observatories. In 1919, the firm was awarded the famous "Poin?on de Gen?ve" or Geneva Hallmark, a token of exceptional craftsmanship and quality.

Today, the firm continues to strive to offer its customers watches worthy of celebrating a watchmaking tradition that goes back over 180 years, by upholding the values of fine workmanship which always satisfies our customers' expectations.

QUALITY BY BAUME & MERCIER

At Baume & Mercier, the art of watchmaking is a continual process. Proud of its past, the firm is honored to develop contemporary collections offering flawless manufacturing quality.

Proud of the Swiss Made label, the firm designs and develops its timepieces in its in-house Design Studio at the Baume & Mercier head office near Geneva and assembles all its watches in its Watch Workshops at Les Brenets in the heart of the Swiss Jura.

DESIGN QUALITY

Before they are launched in production, prototypes are meticulously tested to guarantee the perfect resistance of future timepieces. Tests are dynamic and chemical.

Time measuring instruments are subjected to extreme conditions (heat, saline mist, UV exposure, violent and repetitive impacts, vibration, etc.). Failing one of these tests means total exclusion.

PRODUCTION QUALITY

During production, the assembled watch cases (sealing and finishing) and automatic or quartz calibers (precision and power reserve) are all individually checked to make sure that each timepiece strictly meets Baume & Mercier specifications. Each watch made by the Watch Workshop in Les Brenets undergoes a series of visual and aesthetic checks throughout the manufacturing process.

And to guarantee irreproachable and constant quality, each finished timepiece undergoes a final and meticulous check before being sent to one of our approved retailers. Baume & Mercier therefore continues to accept only perfection, and only manufacture watches of the highest quality

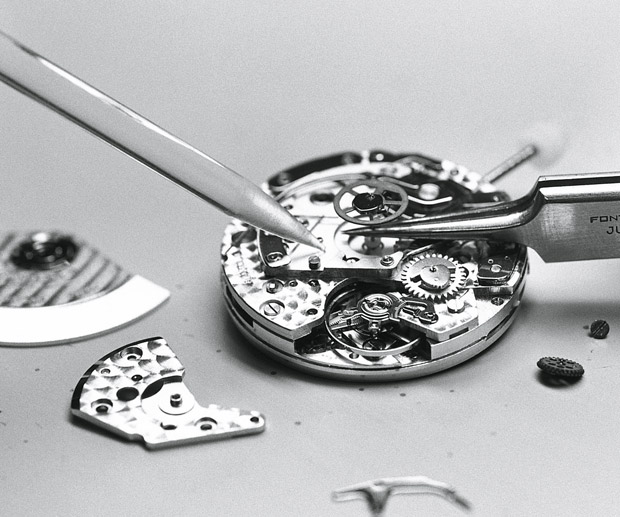

IN THE HEART OF BAUME & MERCIER WATCH WORKSHOPS

All Baume & Mercier watches are produced at our Watch Workshops located in Les Brenets, in the heart of the Swiss Jura mountains. It is there that an assembly process of the very highest quality takes place, based on a traditional method of watch production known in French as "?tablissage" (the division of labor between a range of specialist craftsmen). In its modern form, this method makes it possible to concentrate the expertise of the best collaborators working in the sector, while at the same time maintaining internal control of all key operations and ensuring a very high degree of flexibility.

By working in close collaboration with recognized partners and watchmaking specialists, we have guaranteed access to the best components. We use only equipment, movements and processes that have proved their worth over many years, which makes our watches both reliable and efficient." Daniel Braillard, Director of Industrial Production at Baume & Mercier.

"Accept only perfection. Only manufacture watches of the highest quality"

The original motto of the Baume brothers applies today in the Baume & Mercier Watch Workshops in Les Brenets, in the Swiss watchmaking area, where the same century-old gestures are repeated day after day opposite a typical, fir-clad Swiss landscape. A journey to the realm of the masters of time, to the heart of the workshops where all Baume & Mercier's watches are assembled.

A COMPLEX PUZZLE

A watch is a little bit like a jigsaw puzzle. To start with, it is just a heap of parts all jumbled together, which watchmakers then have to assemble painstakingly together to give life to the final timepiece worthy of a great watchmaking firm. The organization of components and spare parts is thus of fundamental importance and a vital factor in the management of any watch factory. It is at the factory that the parts are received from our suppliers. They are checked, packed and then registered to ensure that all the finishing details comply perfectly with the brand's requirements. The highlight of this stage is the impressive safe-deposit room, where thousands of carefully arranged and labeled spare parts are stored.

DIALS, HANDS AND IMMACULATE CLEANLINESS

First workshop: this is where the most delicate operations are carried out: the installation of the dial and of the hands, and the repairing and casing up of the watch movement. These operations are delicate not only by their painstaking nature (given that they are carried out entirely by hand) but also because they are conducted "open-heart" on the most vulnerable parts of the watch. At Baume & Mercier, these stages are undertaken in a controlled atmosphere zone (CAZ), in which everything possible is done to avoid dust or humidity, the two main sources of potential malfunctions in watches. The air inside the CAZ is permanently filtered, the temperature, humidity and pressure are carefully regulated, and entry to or exit from the CAZ is only permitted to those who wear an anti-static jacket and pass through the airlock.

Inside the zone, in an area that is calm and full of light, the technicians and watchmakers are to be seen leaning over their work stations and peering through their eyeglasses. Their actions are precisely controlled and their tools are carefully positioned. "We are all pretty obsessive about even the smallest detail," laughs Pascal Moulins, the Director of our Watch Workshops at Les Brenets. It is also here that movements are adjusted in order to operate with maximum precision, and that a whole range of tests is carried out, including those to check the water-resistance and airtightness of the assembled watches.

COMPLETION AND EXTREMELY STRICT TESTING

Once they have been cased up, the watches are then transferred to the adjoining workshop. Here there is no longer any need for the "CAZ," since the enclosed watch cases are now airtight and "immunized." They are, however, about to be subjected to a series of stringent tests. The checks undertaken are extremely strict so as to ensure that Baume & Mercier watches are of the very highest quality. Each watch is tested individually. On one side, mechanical watches are placed to whirl around on a winding machine, to test the precision and the power reserve of their movements, and on the other tests are carried out to check the functions: the time setting, date change, chronograph function and any other type of complication. Stringent aesthetic tests are also carried out in order to detect even the tiniest defects. If a problem is identified, the watch is sent back to the "CAZ" for a "return check" by the watchmakers, who then proceed to dismount and repair it. Quartz watches are then subjected to the thermal shock test, which will reveal any possible hidden defects. Finally, the watches are labeled, fitted with their bracelets and packed to be sent to the distribution center, which will then dispatch them to approved Baume & Mercier retailers all over the world.

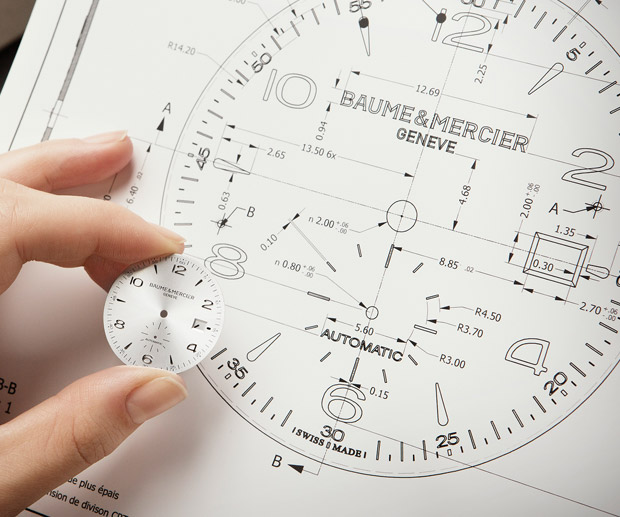

THE DESIGN STUDIO

A mixture of modernity and tradition, of authenticity and creativity, a Baume & Mercier watch is the culmination of a long process of balanced reflection and teamwork. The role of the Design Studio, directed by Alexandre Peraldi, is to manage the delicate creative development of all new Baume & Mercier watches. The secret of the success of the integrated production department located in the heart of the Baume & Mercier head office, near Geneva, lies in finding the right balance between the aesthetics defined by the Design Studio in conjunction with the product development teams and the technical production capacities defined by the technical development engineers.

THE DESIGN PROCESS:

The process leading to the creation of Baume & Mercier watch collections aspires to produce a fusion between the contemporary vision of the Maison and the traditional rules of watch design, while at the same time respecting the principle of the "golden ratio," of which the Phi symbol is the logo of the Maison.

SOURCES OF INSPIRATION:

One thing that all contemporary Baume & Mercier collections have in common is that they always take their original inspiration from a historic model selected from the museum of the Maison. These free interpretations, revisited by the Design Studio with talent and in a spirit of modernity, make it possible to establish the personality of each new model while at the same time elegantly incorporating it into the ever-growing family of Baume & Mercier creations.

THE SOUL OF THE COLLECTIONS:

Thus the Linea, with its pure, timeless lines, is in fact an extrapolation of a small "mass produced" watch model from the 1950s. An emblematic chronograph of the 1940s was used as the connecting motif for the Capeland Collection, while the Hampton model has established itself as the contemporary version of a rectangular-shaped Art D?co model. The Classima line, for its part, is based on the model of an elegant watch first created in the 1960s. Meanwhile the Clifton Collection takes its inspiration from a watch with a pure, balanced design that made its appearance in the Baume & Mercier catalog during the 1950s, the golden age of the wristwatch.

CREATIVE PROCESS: Once the museum piece has been selected in accordance with the orientation to be given to the new collection, the Design Studio begins its reinterpretation of the codes by means of hand-drawn pencil sketches, and then continues its work in the form of digital 2D designs. Once the main aesthetic characteristics have been approved by management, the work of establishing the final dimensions begins.

3D TREATMENT: Establishing the final dimensions requires the prior use of computer design techniques involving 3D software. These designs are finalized by the Design Studio, where product development engineers ensure the feasibility of the technical choices made. Once this stage has been validated, the Design Studio initiates the formation of the models by means of innovative techniques such as stereolithography, a state-of-the-art form of printing capable of giving physical volume to a 3D image by producing a model of it formed in synthetic resin. The finishing relating to the aesthetic appearance of the case is then applied on the basis of a life-size metal model.

PERFECTING OF THE PROTOTYPES: Once the resin models and the metal models have been validated, the first prototypes of the dials, hands and bracelets are produced, so that the finishing of each newly-created model can be best appreciated.

PRODUCTION: After the inclusion of the last improvements, the final prototypes, assembled with the same care and attention as standard production watches, are analyzed in detail before being subjected to the various checks and impact tests designed to guarantee their quality and robustness (wearing tests - accelerated wear and tear test - strength tests). Once all aspects have been checked, production can begin. During the production and assembly phase, a very large number of inspections are carried out to check the perfect compliance of hundreds of components with the specifications established for each Baume & Mercier watch. The final assembly is carried out in accordance with established procedures at our Watch Workshops in Les Brenets, in the heart of the Swiss watchmaking region, and complies with the strict standards first established by the family that first founded Baume & Mercier in 1830, encapsulated by their motto: "Accept only perfection. Only manufacture watches of the highest quality." Our watches are also subjected to all these tests and checks so as to guarantee to our customers that each of our watches has been subjected to constant care and attention during each phase of its production, assembly and packing.

Text & Images taken from Baume & Mercier's website, http://www.baume-et-mercier.com/.